- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Thickness of material (mm): | |

|---|---|

| Insulation: | |

| Heating method: | |

| Construction: | |

| Material: | |

| Availability: | |

| Quantity: | |

DGET- 1000L

DGET

8438400000

| Beer brewing equipment introduction |

The output of beer brewing equipment depends on the type and size of mashing equipment, the size and number of fermentation tanks, and the fermentation cycle of beer.

Mashing system introduction

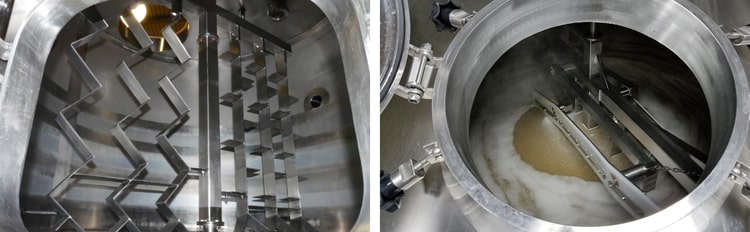

The mashing system is the core of the whole set of equipment and is responsible for the process of making malt into wort. Namely: "mashing-lautering-boiling-whirlpool" four main process steps. These four functional steps are completed by single tank or combined tanks. The hot water tank is auxiliary equipment.

Mash/lauter tuns are built entirely of 304 stainless steel and can be customized entirely to your needs. Whether you are looking for smaller, single tanks for nano/pilot systems or large, full rake agitation systems with combination vessels or separate mash mixer and lauter tuns, we can create the tanks you need for your brewing procedure. All tanks come standard with full CIP, false bottoms, nd hot liquor piping, and heavy duty agitation on systems

Boil/brew kettles are constructed of 304 stainless steel and disperse heat evenly to provide proper sterilization and concentration of wort. Brew kettles are outfitted with multiple drain outlet with tri-clamp fittings for clean and easy impurity removal. Tangential inlets can be installed to create combination boil kettle/whirlpool vessels and cut down the equipment footprint for smaller breweries.

Whirlpool tank are constructed of SUS304 and can be completely customized to your needs. Whether you are adding your whirlpool to an existing system for greater efficiency, or including one in a full upgrade of your brewhouse

Hot water tank is an optional

Electric heating,steam heating or direct fire heating

Except the main brewing tanks, other accessories generally include plate heat exchanger, work platform, yeast add vessel, wort aeration, wort grant and mash pumps,pipes etc.

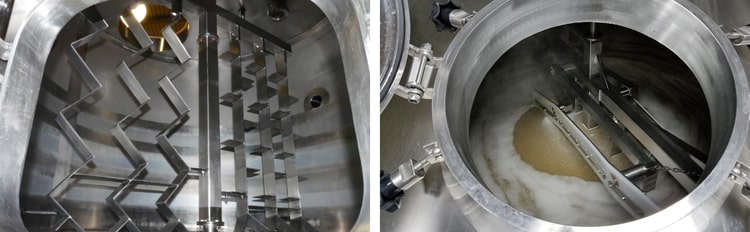

Fermentation system introduction

The angle of the cone bottom is generally 60°-80°, and also 90°-110°, but this is mostly used for large-capacity fermentation tanks. Generally, the diameter-to-height ratio of the tank is usually 1:2—1:4. The tank should not be too thin and high, so as not to cause strong convection and affect the sedimentation of yeast and coagulum. The working pressure of the general fermentation tank is controlled at 0.2MPa-0.3MPa. The inner wall of the tank must be smooth and flat, and the inner wall of the stainless steel tank should be polished

Uni-tank, pressure-tested for carbonation

More than 25% headspace above effective volume

CIP cleaning arm, with 360° coverage via our slotted, rotary spray-ball

CO2 blow-off arm

Rotating racking arm, with easy turn handle

Sample port with perlik style valve

Carbonation stone for single-vessel carbonation

Pressure / vacuum relief valve ("PRV")

Dry hops adding port

High accurency temperature sensor

Available with pressure-tested glycol dimpled jacket cooling system

| Company information |

The complete brewing system also should contain malt crush system,bright beer tank,cooling system,CIP system,control system,kegging or bottling or canning machine,filter system,water treatment device,pasteurization machine and so on.

If you want to know more details,welcome to contact me.

| Beer brewing equipment introduction |

The output of beer brewing equipment depends on the type and size of mashing equipment, the size and number of fermentation tanks, and the fermentation cycle of beer.

Mashing system introduction

The mashing system is the core of the whole set of equipment and is responsible for the process of making malt into wort. Namely: "mashing-lautering-boiling-whirlpool" four main process steps. These four functional steps are completed by single tank or combined tanks. The hot water tank is auxiliary equipment.

Mash/lauter tuns are built entirely of 304 stainless steel and can be customized entirely to your needs. Whether you are looking for smaller, single tanks for nano/pilot systems or large, full rake agitation systems with combination vessels or separate mash mixer and lauter tuns, we can create the tanks you need for your brewing procedure. All tanks come standard with full CIP, false bottoms, nd hot liquor piping, and heavy duty agitation on systems

Boil/brew kettles are constructed of 304 stainless steel and disperse heat evenly to provide proper sterilization and concentration of wort. Brew kettles are outfitted with multiple drain outlet with tri-clamp fittings for clean and easy impurity removal. Tangential inlets can be installed to create combination boil kettle/whirlpool vessels and cut down the equipment footprint for smaller breweries.

Whirlpool tank are constructed of SUS304 and can be completely customized to your needs. Whether you are adding your whirlpool to an existing system for greater efficiency, or including one in a full upgrade of your brewhouse

Hot water tank is an optional

Electric heating,steam heating or direct fire heating

Except the main brewing tanks, other accessories generally include plate heat exchanger, work platform, yeast add vessel, wort aeration, wort grant and mash pumps,pipes etc.

Fermentation system introduction

The angle of the cone bottom is generally 60°-80°, and also 90°-110°, but this is mostly used for large-capacity fermentation tanks. Generally, the diameter-to-height ratio of the tank is usually 1:2—1:4. The tank should not be too thin and high, so as not to cause strong convection and affect the sedimentation of yeast and coagulum. The working pressure of the general fermentation tank is controlled at 0.2MPa-0.3MPa. The inner wall of the tank must be smooth and flat, and the inner wall of the stainless steel tank should be polished

Uni-tank, pressure-tested for carbonation

More than 25% headspace above effective volume

CIP cleaning arm, with 360° coverage via our slotted, rotary spray-ball

CO2 blow-off arm

Rotating racking arm, with easy turn handle

Sample port with perlik style valve

Carbonation stone for single-vessel carbonation

Pressure / vacuum relief valve ("PRV")

Dry hops adding port

High accurency temperature sensor

Available with pressure-tested glycol dimpled jacket cooling system

| Company information |

The complete brewing system also should contain malt crush system,bright beer tank,cooling system,CIP system,control system,kegging or bottling or canning machine,filter system,water treatment device,pasteurization machine and so on.

If you want to know more details,welcome to contact me.