- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Thickness of material (mm): | |

|---|---|

| Insulation: | |

| Matrial: | |

| Heating method: | |

| Control panel: | |

| Availability: | |

| Quantity: | |

DGET-1000L

DGET

8438400000

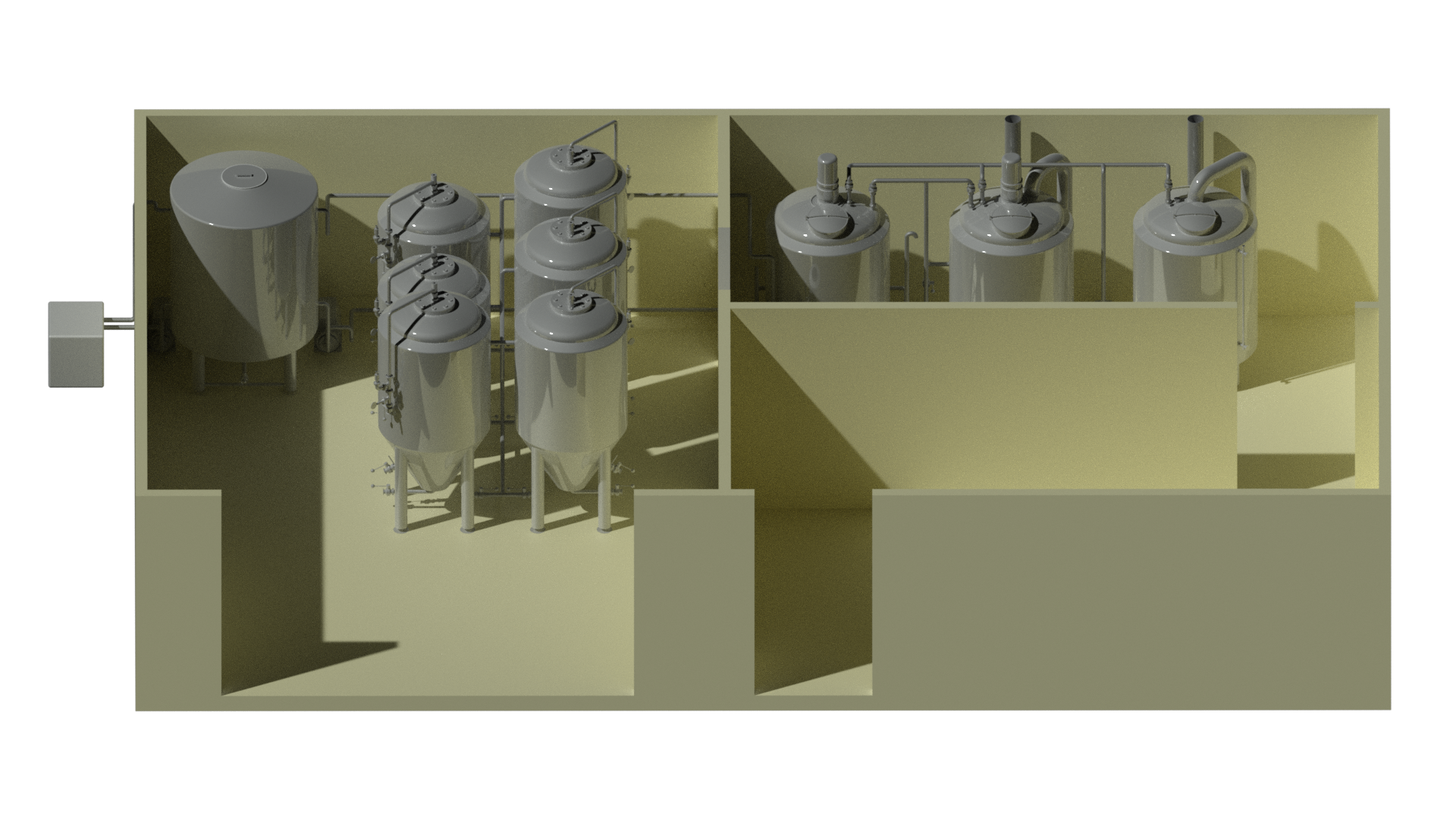

| Turnkey brewery introduction |

Beer brewing equipment is used for brewing a variety of beer , such as ale,lager, IPA and so on. The raw material of beer brewing is four basic ingredients (water, malt, yeast, hops) and some auxiliary ingredients (sorghum, rice).

1000L beer brewing equipment is the most popular type in the market.Because it is not only suitable to private brewery,but also suitable to middle brewpub,restaurant.......

| 1000L turnkey brewery system | |||

| Crushing system(flex auger, miller) | |||

| Mashing system(Mash/lauter tank, kettle/whirlpool tank,double hot liquid tank) | |||

| Fermenting system(fermenter, brite beer tank) | |||

| Cooling system(Glycol water tank,cold water tank chiller) | |||

| Control system(semi-automatic/full automatic) | |||

| CIP system(Cleaning tanks) | |||

| Filter system | |||

| Bottling/canning line | |||

| Sterilization system |

1. Crushing system--Turnkey Brewery

1) Malt miller (Normally,1000L beer will need about 170kg-200kg malt, guarantee to finish milling with half an hour)

2) Flexible auger (Transport malt to mash tank)

2.Mashing system--1000L turnkey brewery(Customzied)

1) 2 vessel brewhouse: Mash/lauter tun, kettle/whirlpool tank,2000L hot liquid tank

2) 3-vessel brewhouse:Mash/lauter tun, brew kettle,whirlpool tank,2000L hot liquid tank

3) 4-vessel brewhouse:Mash tun,lauter tun, brew kettle,whirlpool tank,2000L hot liquid tank

4) Steam heating,direct fire heating and electirc heating

Take 2 vessels brewhouse as a reference

Mash/lauter tank

Equip with: *False bottom *Raker with motor *Balance tank *Wort collection pipe *Spray sparging ring *CIP ball

*Backflush pipe *grist hydrator *

Boiling/Whirlpool tank

Equip with: *Electric heating pipe/steam jakcet *Agitator with motor *Tangential whirlpool inlet *CIP ball

3. Fermenting system--1000L turnkey brewery

1)Fermentation tank

2)Bright beer tank

Fermentation tank-Unitank

Bright beer tank

Equipped with: *Hops adding port *Vacumm valve *CIP pipe *Pressure gauge *Apunding valve *Sample valve *Carbonation stone *Temperaure sensor *

4. Cooling system--1000L turnkey brewery

1)Glycol water tank

2)Cold water tank(Optional)

3)Chiller

*The cooling system is according to tank's capacity and quantity of fermentation tank.We will recommend suitable cooling system for brewery

5. CIP cleaning system

6.Control system

1) Control the whole brewing system

2) Siemens,Omron,Schneider component

| Service |

Pre-Service After-Service

Recommend brewery equipment according to Help customer to install equipment.

customer's requirement.Design appropriate tank's Train customer how to brew beer.

drawing and layout size drawing based on customer's

space.

| Contact us |

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service

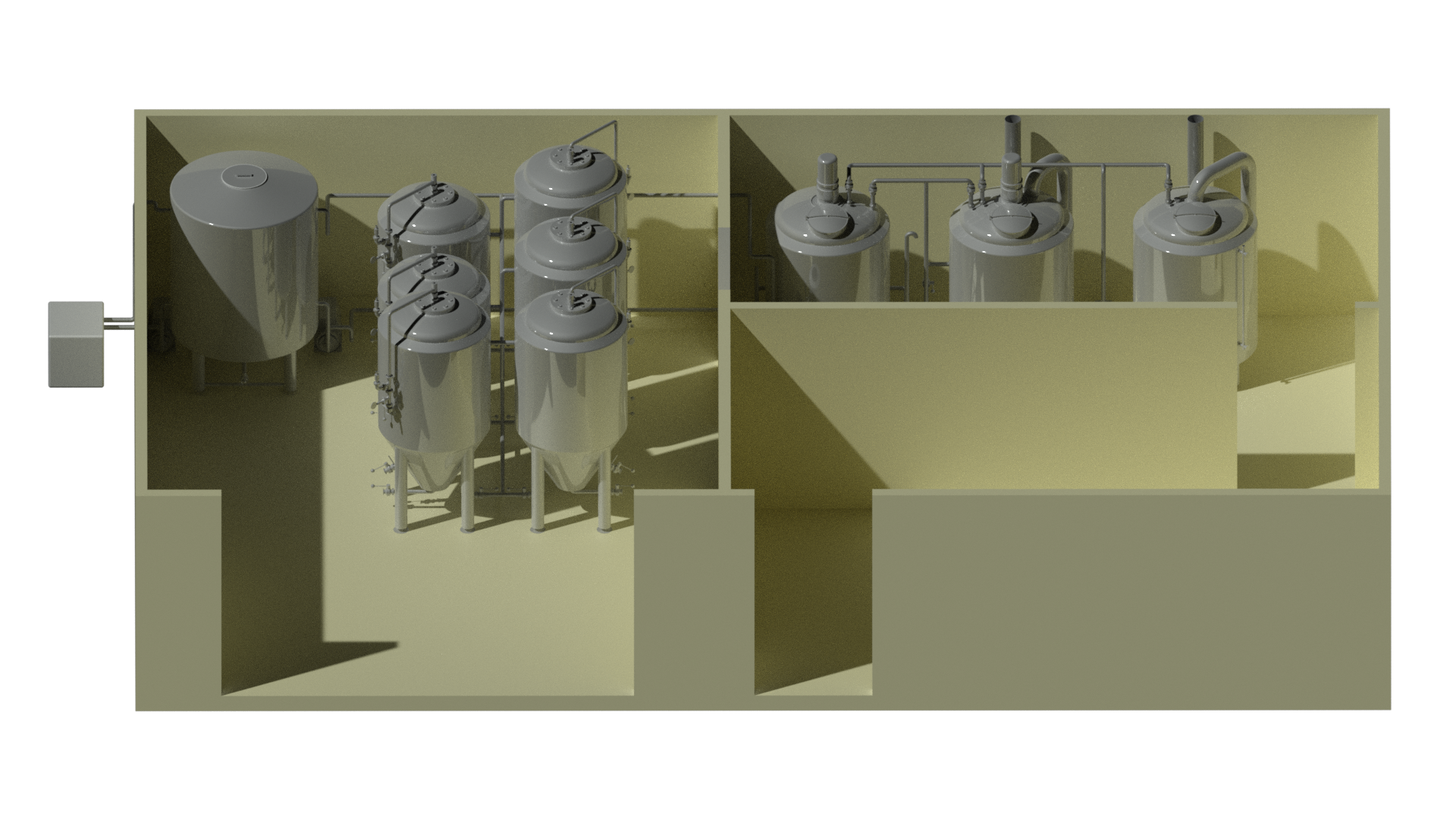

| Turnkey brewery introduction |

Beer brewing equipment is used for brewing a variety of beer , such as ale,lager, IPA and so on. The raw material of beer brewing is four basic ingredients (water, malt, yeast, hops) and some auxiliary ingredients (sorghum, rice).

1000L beer brewing equipment is the most popular type in the market.Because it is not only suitable to private brewery,but also suitable to middle brewpub,restaurant.......

| 1000L turnkey brewery system | |||

| Crushing system(flex auger, miller) | |||

| Mashing system(Mash/lauter tank, kettle/whirlpool tank,double hot liquid tank) | |||

| Fermenting system(fermenter, brite beer tank) | |||

| Cooling system(Glycol water tank,cold water tank chiller) | |||

| Control system(semi-automatic/full automatic) | |||

| CIP system(Cleaning tanks) | |||

| Filter system | |||

| Bottling/canning line | |||

| Sterilization system |

1. Crushing system--Turnkey Brewery

1) Malt miller (Normally,1000L beer will need about 170kg-200kg malt, guarantee to finish milling with half an hour)

2) Flexible auger (Transport malt to mash tank)

2.Mashing system--1000L turnkey brewery(Customzied)

1) 2 vessel brewhouse: Mash/lauter tun, kettle/whirlpool tank,2000L hot liquid tank

2) 3-vessel brewhouse:Mash/lauter tun, brew kettle,whirlpool tank,2000L hot liquid tank

3) 4-vessel brewhouse:Mash tun,lauter tun, brew kettle,whirlpool tank,2000L hot liquid tank

4) Steam heating,direct fire heating and electirc heating

Take 2 vessels brewhouse as a reference

Mash/lauter tank

Equip with: *False bottom *Raker with motor *Balance tank *Wort collection pipe *Spray sparging ring *CIP ball

*Backflush pipe *grist hydrator *

Boiling/Whirlpool tank

Equip with: *Electric heating pipe/steam jakcet *Agitator with motor *Tangential whirlpool inlet *CIP ball

3. Fermenting system--1000L turnkey brewery

1)Fermentation tank

2)Bright beer tank

Fermentation tank-Unitank

Bright beer tank

Equipped with: *Hops adding port *Vacumm valve *CIP pipe *Pressure gauge *Apunding valve *Sample valve *Carbonation stone *Temperaure sensor *

4. Cooling system--1000L turnkey brewery

1)Glycol water tank

2)Cold water tank(Optional)

3)Chiller

*The cooling system is according to tank's capacity and quantity of fermentation tank.We will recommend suitable cooling system for brewery

5. CIP cleaning system

6.Control system

1) Control the whole brewing system

2) Siemens,Omron,Schneider component

| Service |

Pre-Service After-Service

Recommend brewery equipment according to Help customer to install equipment.

customer's requirement.Design appropriate tank's Train customer how to brew beer.

drawing and layout size drawing based on customer's

space.

| Contact us |

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service