- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Thickness of material (mm): | |

|---|---|

| Insulation: | |

| Matrial: | |

| Heating method: | |

| Control panel: | |

| Availability: | |

| Quantity: | |

DGET-500

DGET

8438400000

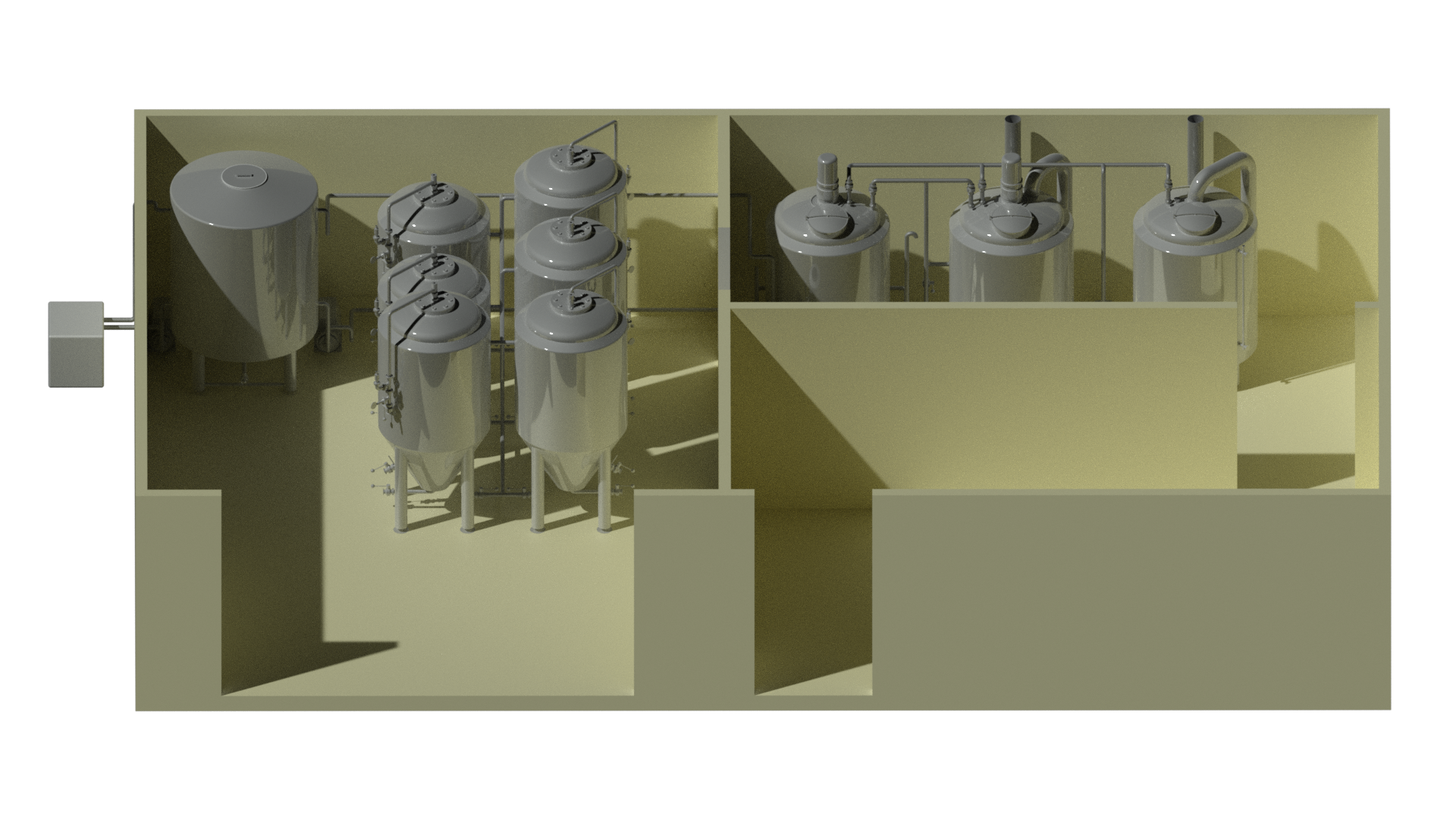

Our 500 litres beer equipment is an excellent small to medium brew pub system! Get your microbrewery or nanobrewery started with variety and flexibility. This 500 litres brewing system is easily expandable as demand grows, and is an ideal brewing system for micro brewery owner, restaurateur and artisan. Our 500l brewery equipment is accord with Germany TUV certification that meet the internationally recognized Standards for Safety, which keeps your brewers safe and avoids major hassles at inspection time.

| 500L beer brewing system |

|

| Mashing system introduction |

The mashing system is both the heart and engine of the brewery where several critical processes in the creation of craft beer are performed. Brewhouses, along with other key pieces of brewing equipment, vary in capacity, features, and complexity, but all brewhouses share the need to wet grain, separate the wort from the grain, and boil the wort with a heating source. The three most common brewhouse heating sources are:

Steam

Indirect Fire

Electric

There are a million different ways to configure your 500l brewhouse. Here are some of the included features:

Fast and easy setup

Advanced touch-screen controls from with remote-control capability

Insulated mash tun with rakes, plow and grist hydrator

Insulated electrically-heated brew kettle

Glass wort grant with automated pump controls

Hard piping and platform

Stairs with wheels for easy access under platform

On demand water supply control optional

Take 2 vessels brewhouse as a reference

1.Mash/lauter tank

This 500l insulated mas/lauter tun) will help the brewer maintain a constant, even, mash temperature. The RAKES are used for better efficiency and ease of use, and the PLOW will help empty the mash tun by scraping the grains out of the side manway. The built in clean in place system (CIP spray ball) and rectangular manway will make this stainless insulated mash tun very easy to clean.

2.Boiling/Whirlpool tank

Our brew kettles are designed with enough capacity to allow for head space for foaming, evaporation, and shrinkage due to cooling. This 500l brew kettle has the ability to both boiling and whirlpool, which will free up valuable floor space in your brewery and will save you money on brewing equipment. Conveniently sized, it does not need a platform, and is wide enough to accommodate 5 bbl and still be operational from the floor for an average sized person.

Other configurations:Mashing system--500L turnkey brewery(Customzied)

1) 2 vessel brewhouse: Mash/lauter tun, kettle/whirlpool tank,1000L hot liquid tank

2) 3-vessel brewhouse:Mash/lauter tun, brew kettle,whirlpool tank,1000L hot liquid tank

3) 4-vessel brewhouse:Mash tun,lauter tun, brew kettle,whirlpool tank,1000L hot liquid tank

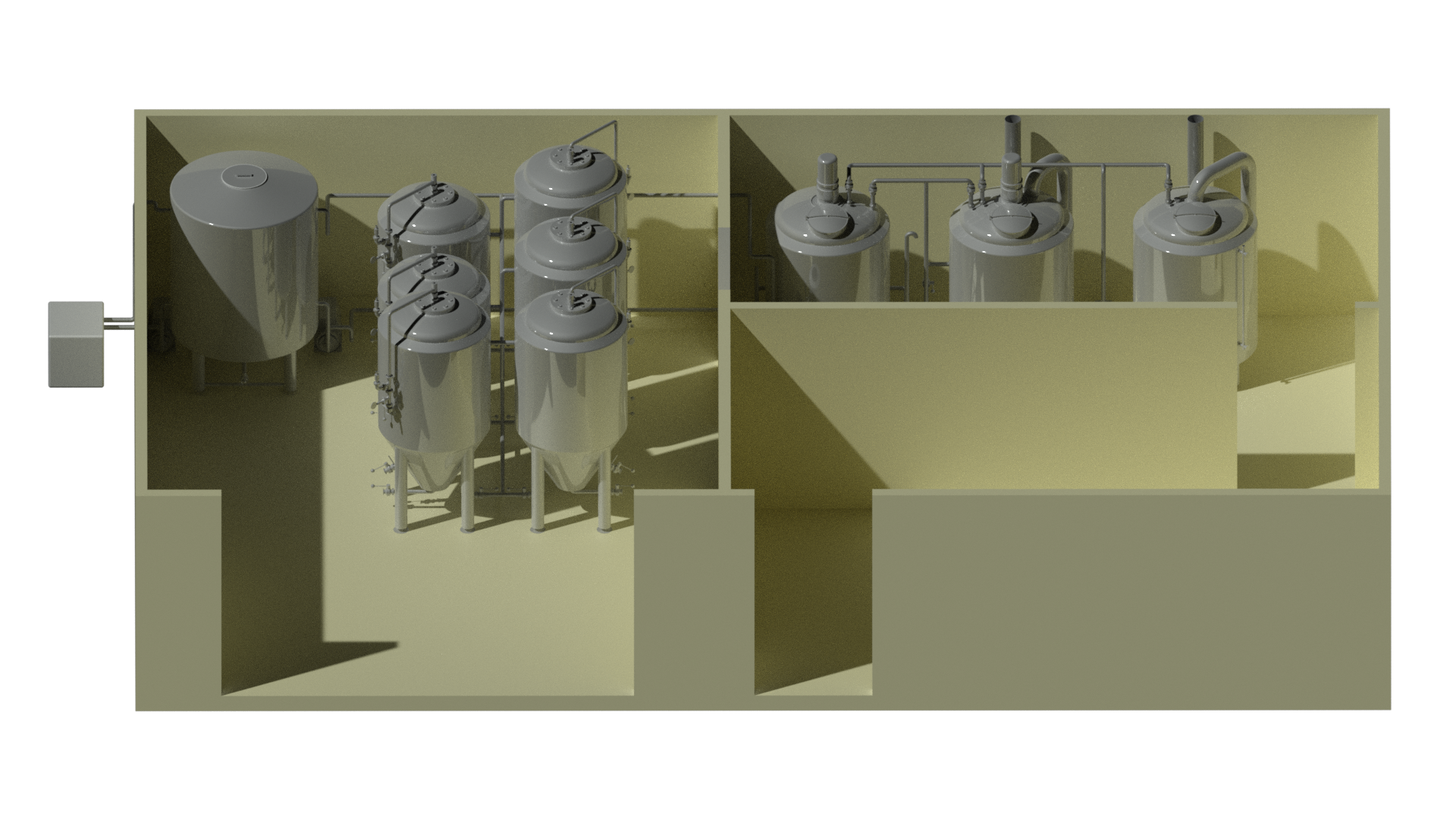

| Fermentation system introduction |

This 500l/1000l conical fermenter features two-zone glycol jacketing that will allow you to precisely control fermentation temperature. Designed for precision and brewing excellence, this 500l/1000l fermenter also features a side manway for more effective cleaning via CIP.

Features of this 500l fermenter:

Shadowless Side Manway for more effective cleaning via CIP

Two-zone jacketing (cone and side wall) for more efficient cooling.

4" Dry hopping port on top of tank

Racking arm for clear transfer

CIP arm

Rotating spray ball

Sample valve for quality testing

(2) butterfly valves

Adjustable feet for leveling on uneven floors or fine height adjustments

Tank material thickness is 3mm

Jacket and outer shell thickness is 2mm

Cone has 60 degree interior angle

Vacumm valve,hops adding hole,pressure gauge,apunding valve,carbonation stone,tempretuare sensor,sample valve,themometer

| Service |

Pre-Service After-Service

Recommend brewery equipment according to Help customer to install equipment.

customer's requirement.Design appropriate tank's Train customer how to brew beer.

drawing and layout size drawing based on customer's

space.

| Contact us |

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service

Our 500 litres beer equipment is an excellent small to medium brew pub system! Get your microbrewery or nanobrewery started with variety and flexibility. This 500 litres brewing system is easily expandable as demand grows, and is an ideal brewing system for micro brewery owner, restaurateur and artisan. Our 500l brewery equipment is accord with Germany TUV certification that meet the internationally recognized Standards for Safety, which keeps your brewers safe and avoids major hassles at inspection time.

| 500L beer brewing system |

|

| Mashing system introduction |

The mashing system is both the heart and engine of the brewery where several critical processes in the creation of craft beer are performed. Brewhouses, along with other key pieces of brewing equipment, vary in capacity, features, and complexity, but all brewhouses share the need to wet grain, separate the wort from the grain, and boil the wort with a heating source. The three most common brewhouse heating sources are:

Steam

Indirect Fire

Electric

There are a million different ways to configure your 500l brewhouse. Here are some of the included features:

Fast and easy setup

Advanced touch-screen controls from with remote-control capability

Insulated mash tun with rakes, plow and grist hydrator

Insulated electrically-heated brew kettle

Glass wort grant with automated pump controls

Hard piping and platform

Stairs with wheels for easy access under platform

On demand water supply control optional

Take 2 vessels brewhouse as a reference

1.Mash/lauter tank

This 500l insulated mas/lauter tun) will help the brewer maintain a constant, even, mash temperature. The RAKES are used for better efficiency and ease of use, and the PLOW will help empty the mash tun by scraping the grains out of the side manway. The built in clean in place system (CIP spray ball) and rectangular manway will make this stainless insulated mash tun very easy to clean.

2.Boiling/Whirlpool tank

Our brew kettles are designed with enough capacity to allow for head space for foaming, evaporation, and shrinkage due to cooling. This 500l brew kettle has the ability to both boiling and whirlpool, which will free up valuable floor space in your brewery and will save you money on brewing equipment. Conveniently sized, it does not need a platform, and is wide enough to accommodate 5 bbl and still be operational from the floor for an average sized person.

Other configurations:Mashing system--500L turnkey brewery(Customzied)

1) 2 vessel brewhouse: Mash/lauter tun, kettle/whirlpool tank,1000L hot liquid tank

2) 3-vessel brewhouse:Mash/lauter tun, brew kettle,whirlpool tank,1000L hot liquid tank

3) 4-vessel brewhouse:Mash tun,lauter tun, brew kettle,whirlpool tank,1000L hot liquid tank

| Fermentation system introduction |

This 500l/1000l conical fermenter features two-zone glycol jacketing that will allow you to precisely control fermentation temperature. Designed for precision and brewing excellence, this 500l/1000l fermenter also features a side manway for more effective cleaning via CIP.

Features of this 500l fermenter:

Shadowless Side Manway for more effective cleaning via CIP

Two-zone jacketing (cone and side wall) for more efficient cooling.

4" Dry hopping port on top of tank

Racking arm for clear transfer

CIP arm

Rotating spray ball

Sample valve for quality testing

(2) butterfly valves

Adjustable feet for leveling on uneven floors or fine height adjustments

Tank material thickness is 3mm

Jacket and outer shell thickness is 2mm

Cone has 60 degree interior angle

Vacumm valve,hops adding hole,pressure gauge,apunding valve,carbonation stone,tempretuare sensor,sample valve,themometer

| Service |

Pre-Service After-Service

Recommend brewery equipment according to Help customer to install equipment.

customer's requirement.Design appropriate tank's Train customer how to brew beer.

drawing and layout size drawing based on customer's

space.

| Contact us |

Why choose us:

1.Always delivery in time

2.Guarantee is 3 years

3.Install equipment freely

4.Real food grade SUS 304

5.Promise good pre service and after service